|

| A mono-crystal ingot is produced from electronic grade silicon. One ingot weighs approximately 100 kilograms (or 220 pounds) and has a silicon purity of 99.9999 percent. |

|

| A lens (middle) reduces the mask's image to a small focal point. The resulting "print" on the wafer is typically four times smaller, linearly, than the mask's pattern. |

|

| The photo resist layer protects wafer material that should not be etched away. Areas that were exposed will be etched away with chemicals. |

|

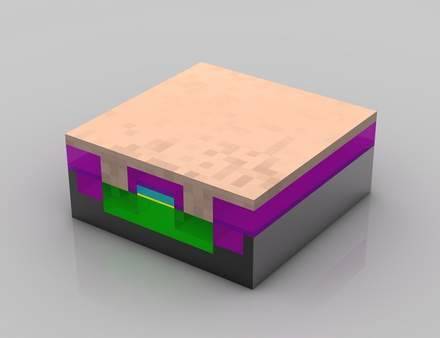

| After the etching, the photo resist is removed and the desired shape becomes visible. |

|

| After the ion implantation, the photo resist will be removed and the material that should have been doped (green) now has alien atoms implanted. |

|

| The copper ions settle as a thin layer on the wafer surface. |

|

| The excess material is polished off leaving a very thin layer of copper. |

|

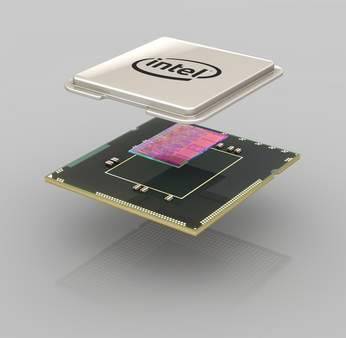

| During this final test the processors will be tested for their key characteristics (among the tested characteristics are power dissipation and maximum frequency). |

No comments:

Post a Comment